Hardinge mill: In this type of ball mills the cylinder has a conical end towards a discharge point. In this mill the larger balls remain within the cylinder and the smaller balls are collected in the conical portion. As a result, coarser grinding takes place in the cylinder portion and finer grinding takes place in the apex of the conical portion.

types of bal milling

Ball mill power draw predicted from the Denver slide rule, kW 0 200 400 600 Calculated ballmill power draw from the m odel derived, kW Data compared Line y=x Fig. 2. Comparison of the ball mill power draw from the Denver slide rule and the proposed model. Dashed line corresponds to y=x.

In end milling, the cutter generally rotates on an axis vertical to the workpiece. Cutting teeth are located on both the end face of the cutter and the periphery of the cutter body. A ball nose end mill, also known as a spherical end mill or ball end mill, has a semisphere at the tool end.

1. The jackup device of wet grate ball mill makes maintenance easy. 2. The hydrostatic and hydrodynamic bearings ensure the smooth operation of wet grate ball mill. 3. The low speed transmission of wet grate ball mill contributes to easy overhaul and maintenance. 4. The oilmist lubrication device guarantees reliable performance of bearings. 5.

General Types of Bearings and How They Work. The ball itself carries the weight of the load—the force of the load's weight is what drives the bearing's rotation. However, not all loads put force on a bearing in the same manner. There are two different kinds of loading: radial and thrust.

Different manufacturers use different type of rollers. "Bowl mills" or Raymond mills use tapered rollers. MPS mill use tire type rollers and are called "roller mills." The "ball and race mills" use spherical rollers. The main characteristics are: Lower investment costs than other types.

Milling cutter. Milling cutters are cutting tools typically used in milling machines or machining centres to perform milling operations (and occasionally in other machine tools). They remove material by their movement within the machine (, a ball nose mill) or directly from the cutter's shape (, a form tool such as a hobbing cutter).

vertical milling machine. OTHER TYPES OF CONVENTIONAL MACHINES. Universal milling machine. Ram type milling machine. Bed type milling machine. OPERATIONS. FACE MILLING. By face milling cutter; END MILLING. By end mill cutter; For machining pockets slots,key way,etc; SIDE AND FACE MILLING. By side and face milling cutter. FORM MILLING. By form milling cutter.

One of the most popular types of lab grinding mills is a jar mill. Jar mills are excellent for grinding virtually any type of sample. Analytical and hand mills are ideal for hard and brittle samples. Lab bead mills are used for cell and tissue culture preparation.

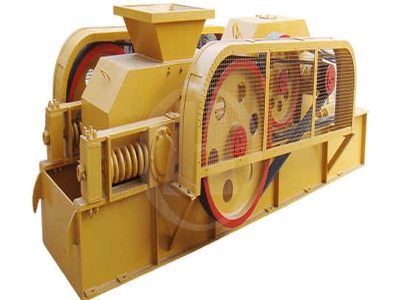

types of balls in ball milling . types of balls in ball milling. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of minerals.

ball milling 3060 min Ar S. F. Nielsen, O. Axelsson, Synth. Commun. 2000, 30, 3501. B(OH) 2 + Br Ac KFAl 2O 3/ Pd(OAc) 2 ball milling Ar c Franziska Schneider, Org. Proc. Res. Develop., 2009, 13,44 Up to 96% yield Entry Rpm T (min) Yield% 1 400 10 92 2 800 5 94

Milling is done using a cylindrical milling tool mounted in a milling tool holder that is then mounted in the tool spindle on the machine. End Mills End mills are the most common milling cutters. End mills are available in a wide variety of lengths, diameters, and types. A square end mill is used for most general milling applications.

The theoretical critical speed of a ball mill is the speed at which the centrifugal force is sufficiently large to cause a small particle to adhere to the shell interior for a full revolution of the mill. The common range of mill speeds is 65% to 80% of critical, depending on mill type, size and the application.

Jul 07, 2017· Size reduction techniques. In some cases, a combination of these may be found in a single mill type. Impact and attrition sizereduction methods include air classifying mills, pin mills, hammer mills and jet mills. Shear, impact and compression methods are used in media or ball mills.

There are many types of grinding machines, and the most commonly used is the ball mill. The ball mill is a piece of grinding equipment which grinds materials into fine powder in a very efficient manner.

The two basic cutting tool types used in metalworking are the singlepoint and multipoint designs. Fundamentally, they are similar. By grouping a number of single point tools in a circular holder, the milling cutter is created. Milling is a process of generating machined surfaces by progressively ...