Jan 07, 2015· CEMENT INDUSTRY Cement Mill Notebook QATAR NATIONAL CEMENT COMPANY DOHAQATAR 2010 na2elll ... and Generation of Heat Heat Generation in Tube Mills Cooling Procedures During Finish Grinding Heat Balance for Mill Cooling Cement Mill Specific Power Consumption Calculation of Cement Mill Power Consumption ...

cement ball mills mass balance

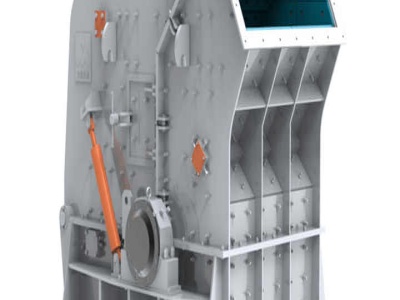

Vertical cement mills are able to reach production values which are significantly higher than the ones achievable with traditional ball mills, in some cases up to 300 t/h. Empirically, It can be estimated through a simple heat balance that in ball mills only 10% of the energy is used to

Independent Specialists in Cement Process Technology Services Trouble shooting process problems with cement manufacturing, kilns, mills and associated equipment. Training courses for Control Room Operators Process Engineers. Preparation of Operating Procedure Manuals, Trouble Shooting and Emergency Procedure Guides.

A useful and simple equation describing the grinding momentum is M x V (mass x velocity), which enables us to see how the Attritor fits into the family of mills. For example, ball mills use large media, normally 1/2" or larger, and run at a low (1050) rpm. The other mills, such as

can be an air swept ball mill or vertical roller mill . flows with heat and mass . a material and energy balance is to be carried out for a raw mill. » More detailed heat balance in ball mill – Grinding Mill China

process parameters, energy and dust concentration, etc. were taken in raw mill, clinkerisation, coal mill and cement mill sections. Heat, Gas and Mass balance of pyroprocessing sections were carried out with ultimate objectives of identifying the potential areas for production optimisation as .

Modelling the performance of industrial ball mills using single ... International Journal of Mineral Processing ... In the multi segment ball mill model, the size dependent material transport within the mill varies ... of the Bond method for sizing wet tumbling mills with a size mass balance simulation model.

Cement Mill Vent/ESP fan load International Cement Review. Cement Mill Vent/ESP fan load. I am getting only 45 kW in a close ckt ball mill ESP fan power . Mill tph 100,dia. m .

tem is steeper than for a cement produced in a ball mill. This is caused by the higher proportion of fine (overground) ma terial present in the ball mill cement, which in turn reflects the greater number of impacts and the inherent inefficiency of ball mill grinding. .

Ball Mill Loading Dry Milling. Ball Mill Loading (dry milling) When charging a ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar use on a jar rolling mill it is important to have the correct amount of media and correct amount of product.

Mar 14, 2017· The bulk weigh of the grinding balls is necessary to understand the grinding balls mass in the cube, the grinding balls mass loaded into the mill, the prevention of mill overloading with grinding balls, etc. These data often used in operational management of grinding process. Consider a definition technique the bulk weight of new grinding balls.

calculate the retention time of cement in a cement mill. Optimization of continuous ball mills used for. The optimal retention time depends not only on the feed material and the desired comminution result but also on the ball charge filling ratio and particularly on the ...

Concrete international / november 2009 41 by Dale P. bentz, eDgarDo F. Irassar, brooks e. bucher, anD W. Jason WeIss Limestone Fillers Conserve Cement Part 1: an analysis based on Powers' model "Green" concrete has become a rallying cry for the twentyfirst century. In addition to its field performance, a concrete mixture is now judged by its

Ball Mill Manufacturers: As a leading turnkey cement plant manufacturer, we design and supply ball mills for cement industry. We expertise in heavy fabrication with largest workshops in Delhi NCR in India with all latest equipped and technologies required for cement plants for up to 3000 TPD production.

AN EXPERIMENTAL ANALYSIS OF VIBRATION OF A BALL MILL WITH VARIABLE LOAD Salkan Rahmanovic Cement Plant Lukavac Bosnia and Herzegovina Safet Isic Mechanical Faculty Mostar Bosnia and Herzegovina ABSTRACT This paper deals with the experimental investigation of vibrations of a ball mill under variable load.

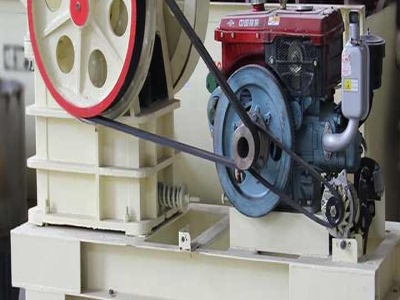

Mar 31, 2008· Modern installations draw power of 210 MW. The power (in kW) required to turn a ball mill is approximated by: P = d () m n where d is the internal diameter in metres, j is the fraction of the mill volume occupied by media, m is the total mass of media in the mill, in tonnes, and n is the mill speed, rpm.

At each stage of adjustment, heat and mass balance is carried out to record the improvements. 3. Electrical Energy. Large fans and Mill drives are the major consumers of electrical energy in a cement plant. The fan power in the Pyroprocessing system is also linked to the thermal efficiency of the system.

ball mill, grinding, automation, optimization, efficiency ... for cement plants where clinker is grinded, for ceramic plants where clay is grinded and for other plants. A specific feature in running a ball mill is that the grinding mills are big power consumers, since grinding ... The output signals of all the transducers are 4 20 mA and they ...

The simulation can then be used to size an entire comminution circuit including crushers (Jaw, Cone and HPGR), screens, SAG/AG mills, Rod Mills, trommels, classifiers, Ball Mills, Pebble Mills and the sizebysize mass balance generated by default can be used to .

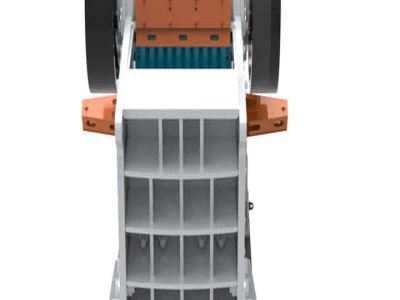

A cement mill is the equipment that used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills. Cement clinker is usually ground using a cement ball mill. This is essentially a large rotating drum containing grinding media normally steel balls.

VEGA Casting Media Grinding Balls For Mining and Cement Plants HS . Description about CASTNNG grinding media balls; Casting grinding media balls also called casting grinding ball, casting steel grinding ball, iron balls. Application : Super SAG, for SAG mills; Grind, for ball mills.

Apr 01, 2015· Read "Analysis of specific discharge rate functions in industrial scale cement grinding multicompartment ball mills to assist ball mill modeling, Minerals Engineering" on DeepDyve, the largest online rental service for scholarly research with thousands of academic publications available at .

MVR vertical roller mill from Gebr. Pfeiffer with patented multiple drive system MultiDrive® for the highest throughput rates and permanent plant availability Cement mills and raw mills .