Adana Cement Industry Inc. operates four separate clinker production lines, two coal mills and five cement mills at its Adana plant. Expert Optimizer (EO), which is an ABB's Advanced Process Control () software product for minerals and cement, is a computer based system for controlling, stabilising and optimising industrial processes.

coal mill in cement

Fire damages coal mill at Essroc Cement in Lower Nazareth The ... Jan 10, 2016 ... LOWER NAZARETH TOWNSHIP — A fire that started Sunday afternoon in the coal mill at the Essroc Cement plant in Lower Nazareth is under... More details » Get Price

The steel ball is the grinding body of the Coal Grinding Mill. The amount of the steel ball of the Coal Grinding Mill is too small, and the impact and grinding effect on the material is small, which does not meet the grinding requirements; the amount is too much, the amount of material is reduced, and the grinding body interacts.

Coal Mill Cement Plant, Coal Mill Cement Plant Alibaba offers 1,019 coal mill cement plant products. About 19% of these are mine mill, 5% are cement making .

The coal, which will be used to fire the cement rotary kiln, will be ground to a product fineness of 15% residue 90µm. The mill with an installed power of 570kW is designed for a finished product rate of 40 t/h.

Cement Mill Reconditions Over a Dozen Coal Mill Rollers in Only 9 Days Working around the clock, seven days a week, a major cement mill located in the MidAtlantic region of the United States produces over 4,000 tons of cement each day.

Vertical coal mills in cement industry,vertical shaf kiln . Vertical coal mill. Vertical mill is a large ideal grinding machine, and it is traditionally used in cement industry, electrical energy, metallurgy, chemicals, non ...

Coal mill is major equipment of cement plant and used for drying and grinding coal. The equipment mainly consists of feed device, main bearings, rotating parts, drive device, selling device, highvoltage startup device and lubrication system. As the "black blood of industry", coal is usually ground into micro size powder, which can ensure a high combustion efficiency. However, different degrades of coal are .

COAL MILL OPERATION. SAFETY ASPECTS 2 Coal Shop Safety 2 SOLID FUELS Coal Petroleum coke (sulfur % ) Delayed coke: the most common Non grindable fluid coke Shot coke (as impurity in delayed coke) Lignite Charcoal (moinha) 3 Coal Shop Safety FUEL DRYING GRINDING SYSTEM Flowsheet of Grinding Drying System Grinding Drying System Pulverized Coal Pulverized Coal Silo Hot gases Dust .

Coal mill (coal pulcerizer) is the essential machine used in cement plant, because coal is the important raw materials in cement production line. Coal powder after grinding by coal mill enter into the rotary kiln toghter with cement raw meal for burning

The cement mill is mainly used to grind cement clinker in cement production process, and it also applies to grinding various ores and other grindable materials in industrial and mining enterprises such as metallurgical plant, chemical plant and power plant and so on. Our company has more than 40year experience on the manufacture of cement mill, the quality of our product takes a leading place around .

Feb 01, 2018· The cement manufacturing process flow chart is shown as follows: Line is the main raw material for cement production, each producing a ton of for more than 30%, coal mill about 3%, accounting for about 40% of cement grinding.

VERTICAL ROLLER MILL SERIES . cement plant/cement machinery/cement equipment . As one of the important manufacturers in cement industry in our country, our company starts the equipment technology development of roller mill in recent years.

Calculation Of Cement Ball Mill Capacity. Cement ball mill, cement clinker grinding mill for cement plant. Cement ball mill is used to grind crushed cement clinker, gypsum rock . coal etc. for cement mill in cement production line is of low cost, high capacity etc.

coal mill cement industries coal mill in cement plant m. Alibabam offers 1,274 coal mill in cement plant products. About 12% of these are mine mill, 11% are crusher, and 1% are grinding ...

Re: Coal Mill Pulverized Coal 200 Mesh. I presume this was pulverised coal rather than clinker from a coal mill? It is possible that the coal has become easier to grind. Has the source of coal been changed? It is possible that the sieve being used has developed a hole. Has the sieve been changed?

what is the role of coal mill in cement aardappelpureeeu role of coal mill in cement manufacturing The electrostatic precipitator comes after the raw grinding system and its role is to This coal mill system has a production rate of 20, cement and coal mill,, Get a Price; Coal in the cement industry

Coal Mill Coal mill is an important auxiliary equipment for coalpowder furnace, it has three methods to crush the coal lump and grind them into powder,it is crushing, impacting and grinding. Air swept coal mill is the main equipment in cement plant for both drying and grinding of the powders.

This practice can reduce the grinding energy use by 510% in some mills, which is equivalent to estimated savings of 35 kWh/t cement. CO2 Emission Reduction Potential CO 2 emissions can be reduced by kg/tcement with this technology.

Coal mill,Coal grinding mill,Crushing mill,Coal powder ... In coalfired power plants coal mills are used to pulverize and dry to coal before it is ... Coal mill is major equipment of .

ALAMEDDIN AND LUZIK ON COAL DUST EXPLOSIONS IN THE CEMENT INDUSTRY219 ignite coal accumulations in the mill under certain conditions. Feeding hot coals from storage piles into the pulverizer may also provide an ignition source. Defective electrical equipment is .

The hot air supply temperature was controlled by bleeding in ambient air so that the coal/air mixture leaving the mill was below the 80100°C upper limit to avoid explosive conditions. All such installations were further protected with explosion doors. Ball mills for cement milling. The early multichamber mills had typically 3 or 4 chambers.

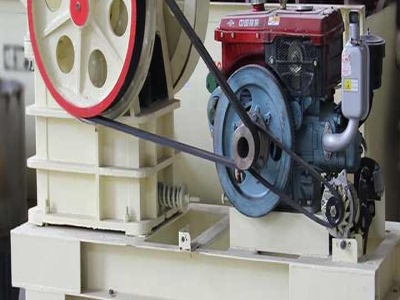

![coal crusher in cement industries[crusher and mill]1](/i0m6h9y/498.jpg)

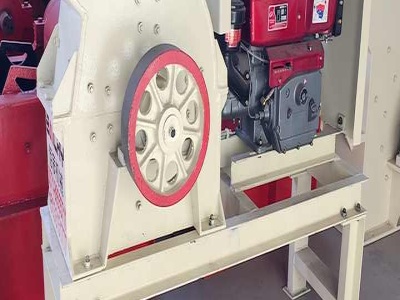

![coal crusher in cement industries[crusher and mill]2](/i0m6h9y/440.jpg)