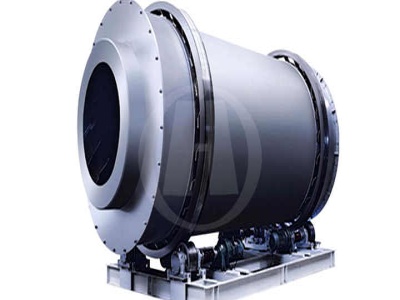

Aug 09, 2015· Ball Milling A ball mill is a key piece of equipment for grinding. It is widely used for cement, silicate products, new type building materials, fireproof materials, chemical fertilizers, black and non ferrous metals, glass, ceramics, etc. Ball milling increases the surface area of a solid ma terial and allows preparation of the desired grain ...

ferrite ball milling fe powder

Substituted Magnesium Ferrite with Composition MgCa x Fe 2 x O 4 ( =,,,, ) ... e mixed powder was then transferred to electric ball mill for hours. e dried powder was pressed into pellets and presintered at a temperature of Cforhourswitha

Nov 15, 2013· Read "Synthesis and characterization of the NiFe 2 O 4 /Ni 3 Fe nanocomposite powder and compacts obtained by mechanical milling and spark plasma sintering, Applied Surface Science" on DeepDyve, the largest online rental service for scholarly research with thousands of academic publications available at your fingertips.

The reactivity of reagent mixture was investigated by thermogravimetric and calorimetric analyses. The ball milling was performed in a AGO2S high energy planetary ball mill with a vial rotation speed of 2220 rpm using steel grinding balls. The milling times were 0, 5, 15, 30 or 60 min.

The samples of hexagonal Srferrite powder were prepared by milling a mixture of SrCO 3, αFe 2O 3 and 2SO 4 (technically pure, the numbers indicate molar ratio) in alcohol under ambient condition for 50h using a roller ball mill. After drying at 100 C for 12h, the superfine powder was kept inside

The samples were prepared by the highenergy mechanical milling of Fe powder with paraffin in the ratio of 80:20 vol. %. The starting Fe particles had a stonelike shape, with the size of less than 5 µm. Mechanical milling was carried out in a planetary ball mill Fritsch P7. .

study the effect of highenergy ball milling on magnetic behaviour of the spinel ferrite 2 Experimental Details Bulk particles of were synthesized using standard solidstate reaction technique. The stoichiometric amount of MgO, MnO and Fe2O3 was mixed thoroughly and preheated at 1000°C for 12 h for ...

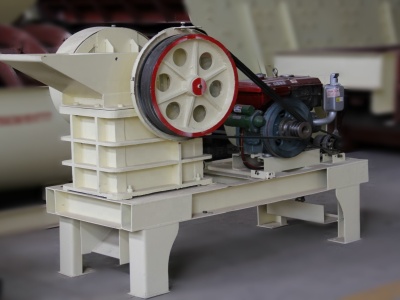

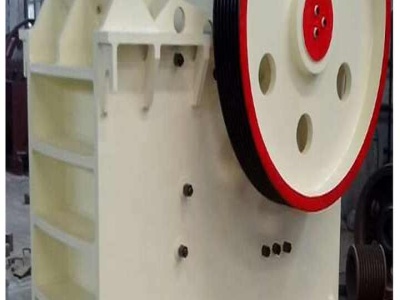

In the batch mode, material is charged into the mill at the top, ground for a predetermined time, then discharged through grids at the bottom. The system can easily be sealed for grinding under inert gases such as nitrogen or argon. The SD Attritor is also used to make dispersionstrengthened metal (DSM).

The milling effect on nickel ferrite particles studied using magnetization measurements and Möss spectroscopy. ... Synthesis of Fe3O4/Fe nanocomposite powder from Fe2O3 and Fe powder by mechanosynthesis. Structural, thermal and magnetic characterisation. ... Transformations in oxides induced by highenergy ballmilling. Dalton ...

Further grinding in a ball mill generates lamellar copper. Mechanical milling of aluminum powder using Semantic Scholar. Kakuk et al. (2009) modelled the milling process in a planetary ball mill and found a relationship between the angular velocity of the sundisk and the vials, and the geometrical parameters of the mill.

Section S1 Reports about steel contamination during the mechanosynthesis of zinc ferrite and some related spineltype ferrites (Table ... 30:1Uni ball mill 200 Vacuum Fe O 4 No/ reduction of Fe3+ ions due to the breaking of FeO bond ... The main disk rotation speed was 500 rpm and the powdertoball weight ratio 1:20. The milling time ...

A flexible permanent magnet is described that contains singlecrystalline ferrite particles embedded in an elastomeric binder. The ferrite particle size is much larger than that of the ferrites in the priorart flexible magnets which results in greatly improved magnetic and mechanical properties.

High frequency properties of ferrite/FeSiAl alloy soft magnetic composites Charalampos A. Stergiou1*and Vassilios Zaspalis1 ... hours in air and ball milling for 3 hours. The milled powders were then annealed at 1100°C for 4 hours ... High frequency properties of ferrite/Fe .

coevaporation, hydrothermal synthesis, high energy ball milling, chemical coprecipitation, microwave irradiation and ultrasonic irradiation method[9, 10]. In this paper, nanocrystalline nickel ferrite, NiFe 2O 4, was synthesized by coprecipitation method. The synthesized nanoparticle was characterized by powder Xray powder

of milling time 3. Magnetic properties: 5h Rietveld refinement shows that after 110h milling the powder contain 97,5 % of nanostructured Zn ferrite XRD patterns were fitted using two phases with a close lattice parameter ( two spinel like structures with different degree of ion exchange between Zn++ and Fe.

in the ingot and the alloy breaks down into a fine powder. This process is known as Hydrogen Decrepitation (HD). The HD powder is then broken up further by a jet milling stage which reduces the particle size to around 5mm. It must be noted that when the alloy is in a powdered form then it is very flammable and must be handled under an inert gas.

Microstructure and Magnetic Properties of NanoSized BaAl Ferrite Particles by High Energy Ball Milling. Journal of Nanoscience and Nanotechnology, 2012. BoSik Kim. Download with Google Download with Facebook or download with email.

Jan 25, 2008· The surface structure of zinc ferrite particles is sensitive to ball milling conditions and we observed that these surface effects greatly impact the MCE and our observations could provide a route for its potential enhancement by controlled surface modification.

Preparation of Strontium Ferrite Powders by Mechanochemical Process ... "Preparation of Strontium Ferrite Powders by Mechanochemical Process", Applied Mechanics and Materials, Vols. 110116, pp., 2012 ... A planetary ball mill was used to grind the starting mixtures. During the grinding process, XRD analysis was employed to make clear ...

Apr 28, 2019· The magnetic system of magnetic separator is a compound of fine ferrite material and rare earth magnets and the average magnetic induction intensity .