Poured concrete driveways are one of the preferred driveways types, offering a permanent lowmaintenance driveway. Concrete can be poured to form patterns or sections, allowing for contraction and expansion of concrete. Concrete paved driveways are more expensive than asphalt but they can last for decades without decaying.

gypsum concrete concrete making materials

When making concrete it's important to use the correct concrete mixing ratios to produce a strong, durable concrete mix. To make concrete there are four basic materials you need: portland cement, sand, aggregate (stone), and water.

GypCrete 2000 ® / gypsum floor underlayment is engineered to deliver compressive strengths up to 3,200 psi ( MPa), also delivering enhanced resistance to surface abrasions and even faster drying time. It's ideal for use over wood or concrete subfloors in single family, light commercial, and multifamily construction, as well as ...

Wet concrete may get trapped inside rubber boots or gloves or gradually soak through coveralls. Concrete finishers kneeling on fresh concrete have had their knees severely burned. Corrosive bleed water from the concrete is absorbed by the worker's pants and held against the skin for .

The components of concrete – cement (limestone, clay and gypsum) and aggregate materials – are chemically inert and therefore virtually noncombustible. Concrete also has a slow rate of heat transfer, which means that concrete walls in a home act as a fire shield, protecting adjacent rooms from flames and maintaining its structural ...

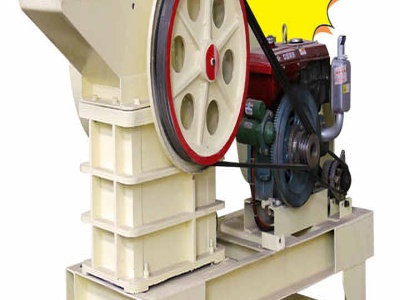

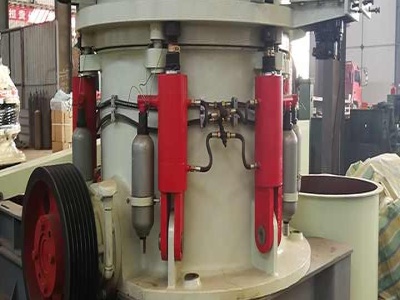

After the clinker is cooled, cement plants grind it and mix it with small amounts of gypsum and limestone. Cement is so fine that 1 pound of cement contains 150 billion grains. The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projects.

The QUIKRETE® Companies are the largest manufacturers of packaged concrete in the United States and an innovative leader in the commercial building and home improvement industries. ... If you have a question regarding technical data, please call us at . DIVISION 3 CONCRETE ... Gypsum Cement Underlayment. FastSetting ...

Oct 07, 2013· GFRC is an ideal material for creating concrete furniture, such as the examples included below. Furniture Pieces that Showcase GFRC To illustrate what GFRC can do in furniture form, Jeffrey Girard describes three projects — a table, a lounge chair and an S chair — that show off the strengths of the material.

Making Gypsum Board. Supplement to Construction Dimensions Magazine. Gypsumation provides essential gypsum board information to A/E/C professionals, contractors, and code officials twice annually. Receive your complimentary electronic issue by signing up, below.

4 Shielding by building materials Concrete blocks Concrete blocks with hollow cavities inside were tested for walls one, two and three blocks thick. The study did not test the shielding value of the blocks if filled with concrete. It would probably be slightly less than a solid concrete wall of the same thickness. Masonry block (concrete block)

Bentley Advanced Materials carries urethane and silicone rubbers which can be brushed on, poured on, or sprayed onto an original model. Once the mould rubber cures, the moulds can be used to make architectural elements, concrete stone veneer, formliners, concrete countertops, GFRC panels, concrete statues and furniture and more.

The first step in making concrete is to prepare the cement. One type of cement, Pordand cement, is considered superior to natural cement because it is stronger, more durable, and of a more consistent quality. To make it, the raw materials are crushed and ground into a fine powder and mixed together.

May 18, 2015· Concrete hollow block can be produced by block making machine, the product is mainly used to fill highlevel framework, because its light weight, sound insulation, good thermal insulation effect, the majority of users trust and favor. Its raw materials are: Cement. Production of fly ash aerated concrete hollow block

Molds made with Mold Star® will last a long time in your mold library and are good for casting wax, gypsum, resins, concrete and other materials. Knife Available at Home Depot Hot Glue Gun Available at Home Depot RYOBI 18 Volt Cordless Drill Available at Home .

The cost to Apply Gypsum Plaster starts at per square foot, but can vary significantly with site conditions and options. Get fair costs for your SPECIFIC project requirements. See typical tasks and time to apply gypsum plaster, along with per unit costs and material requirements. See professionally prepared estimates for gypsum plastering work.

Liquid rubber is a great way to make durable perfectly smooth molds. There are two main suppliers of urethane rubber for concrete molds: SmoothOn and Polytek. Both make polyurethane rubbers that come as twopart liquids (resin and hardener). Polytek recommends using a 7445 or a 7560 material for concrete countertops.