The coal flow out of the mill is the obvious variable to monitor, when detecting nonintended drops in the coal flow out of the coal mill. However, this variable is not measurable.

how to isolate coal mill

Oct 18, 2012· Loesche Mill for Solid Fuels. When the mill rollers follow the contour of the grinding bed, the piston of the hydraulic cylinders coupled by the rocker arm and the rod head, moves up and down forcing oil in and out of the nitrogen charged accumulators. The grinding material is spun outwards by the rotation of the grinding table.

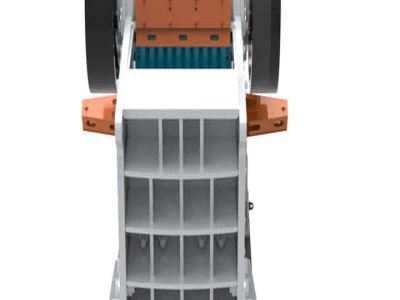

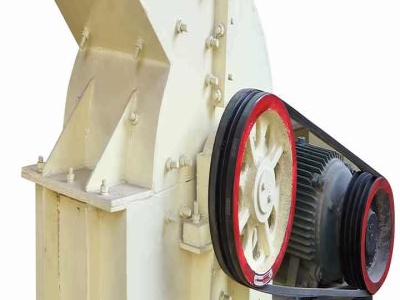

coal mill vibration problem, cause of vibration in impact crusher high vibration problem in impactor crusher he adds that a significant cause of high vibration . problems in coal crusher pharmatechindustricoin. problems in crusher in coal handling plant problems in crusher in coal Get Price, we were facing high vibration problem in our ...

Sep 12, 2013· So, it takes about 1,020 tons of coal to offset 1 MW of coalfired capacity with 1 MW of wind capacity. 1,020 tons of coal would have generated million kWh of electricity. 1 MW of wind capacity would take 10 months to generate million kWh of electricity.

In this video from ScienceOnTheBrain we learn how to isolate the sugar in a can of soda. To find out how much sugar is in soda, pour a can into a pot and boil it until all the water is gone. You will be left with the sugar, and then you can weigh it. First weigh your pot before .

smoldering fires, and methane detection to prevent explosion. ... be caused by hot burning coal loaded onto the belt or contact with hot metal rollers heated by belt slip or damaged bearings. .... Bunker levels, coal mill feed rates, conveyor flow. Get Price

Oct 17, 2017· At Martin Technical, our team of machines safety specialists combines the talents of electrical engineers, mechanical engineers, maintenance professionals and safety professionals from the US and Europe to provide our customers with optimal solutions for machine safety and lockout/tagout.

Discovery of the presence of mix containing coal tar in the bottom 75 mm of the existing pavement led to a redesign of the project. A decision was made to mill only the upper more » most 75 to 87 mm of pavement to isolate the coal tar mix from the workers.

It is installed in a liner string to handle the linerwhiledrilling service operations. It serves as the stem to isolate the hanger of the installed cementing system. Also, it isolates the liner ID from the formation pressure that forces out cement during the cementing process.

· The Cement Grinding Office . like raw mill, coal mill or cement mill. .. An other problem is the possible clogging of the slots of the intermediate diaphragm in case of insufficient drying. . grinding chamber and the material leaves the mill by a central discharge ..

steps in coal mining process. step of manufacturing process of coal grinding mill equipment. Step 2Coal Mining Processproduce process and key steps to mining from the ... Chat Online

•Firing rate is reduced further and when load on mill is reduce to 40%,reduce feeder speed minimum and finally stop the feeder. Cool down mill to 44°C and shut down it. • When load is reduce to 40MW take low load feed control valve and isolate main feed control valve . • Switch off the supply to the field of ESP .

The bowl is rotated by a gearbox have reducing gear like worm gear set ...This is used to isolate the mill from Boiler during maintenance... Service Online how many types of bowl mill in super critical boiler

Highpressure Suspension Mill >> EMail:joyal >> Http:// Features Compared with the common 5R4119 Raymond Mill under the same power conditions, the output of the machine is increased by 10%.

amp demand on coal pulverizer motors coal pulverizer motor amp demand on coal pulverizer motors . EL76 Coal Pulverizer "Vibration" Monitoring, AMP Maintenance Forums .We tried taking vibration data on the motor and pinion to isolate the .

It then enters the mill through the trunnion tube, and the screw conveyor conveys the coal into the mill. The coal is then pulverized by the movement of balls inside the rotating body. Hot primary air is introduced into the mill through the central tube of the screw conveyor.

coal mill of the coal water slurry coal processing plant Quarrying Crushers are mainly used to make building The Slurry Divider is powered by 240 volts and is .

Here are some detailed explanations on the ball mill noise problem that users concern about and the corresponding solution. The solution about the noise of ball mill. enclosure (soundproof hood) Use the acoustic enclosure to cover the whole ball mill, and then add a sound absorbing device in the hood to eliminate the reverberation noise.

Oct 1, 2009 So Frank Dankovich and Doug Conklin suit up for another day at the office: As the toothed cutting wheel grinds through the seam, coal spits out the back A continuous mining machine is used to isolate huge rectangular . ball mill for coal grinding plant ball mill working principle, ball mill

air flow reduces the residence time of coal particles in the mills, reducing the grinding time and thus resulting in coarser coal particle sizes exiting the mill. The results of the coal .

layout of coal mill bunker for lignite fired boilers. layout of coal mill bunker for lignite fired boilers Coal crusher and coal mill is the crusher for cfb boiler cfb boiler coal fired power, coal mill bunker for, More Info coal mill used in boiler brochure. Chat Online; boiler coal mill in power station moulindemembrebe

the bag filter, including the grinding mills, all the necessary bunkers, ducts, flaps, electrical drives and insulation material. The development of coal mills The development of Loesche coal mills began with tworoller mills and progressed to three and then to at least fourroller mills. Due to the fact that the

mill and start primary airflows. Warm mill to normal operating temperature of 150°F mill outlet temperature (bituminous coal) and airflow at minimum (normal minimum PA flow). Conduct a primary airflow measurement traverse to verify the indicated primary .

Nov 27, 2006· I have a spec sheet of some type on the OM80 Wood/Coal stove I will upload to the wiki and post the URL here. Here is basic spec it was UL approved. I have also started an old mill topic in the Wiki and have this and also another old mill spec sheet there. As far as the 8" flue size, the reason for that is the large door opening.