Cyanide Leaching Of Gold . ... Another element that plays with the cyanide chemistry is nickel. Nickel, however does not interfere with the gold going into solution, but rather the precipitation of the gold from the cyanide solution. ... One is the MerrillCrowe zinc precipitation process and the other is the adsorption of the gold onto ...

nickel extraction process

A Review on Solvent Extraction of Nickel . Sejal Chauhan*, Assistant professor, Department of chemical engineering, Faculty of engineering technology and research, ... Solvent extraction is a suitable process for reducing solute concentrations in aqueous streams [2].

Apr 28, 2014· The process doesn't only mean that nickel extraction from lowgrade ore will become an economically viable possibility; it will become an environmentally viable possibility as well. During the process all NOx gases are captured and converted to reusable nitric acid and any leach residue is mainly silicates with minor residual nitrate content.

Cobalt extraction refers to the techniques used to extract cobalt from its ores and other compound ores. Several methods exist for the separation of cobalt from copper and nickel. They depend on the concentration of cobalt and the exact composition of the used ore.

Mine production: 230,000 MT. The Philippines has been a top nickel producer and nickel ore exporter for quite some time. But last year they country's nickel production .

Description. Nickel, cobalt and platinum group metals are key elements for materials processing. They occur together in one book because they (i) map together on the periodic table (ii) occur together in many ores and (iii) are natural partners for further materials processing and materials manufacturing. They all are, for example,...

background of the SMMC Process (Sumitomo Metal Mining Co., Japan). Here, the nickel(II) and cobalt(II) chloride solutions, being the feed for selective extraction of Co(II), are obtained and preliminary purified from most of the contaminants by their common extraction from the sulphate solutions with the Versatic 911 (Shell Chemicals

Extraction of metals. The process of extracting metal ores buried deep underground is called Mining. The metal ores are found in the earth's crust in varying abundance. The extraction of metals from ores is what allows us to use the minerals in the ground! The ores are very different from the finished metals that we see in buildings and bridges.

Nickel, cobalt and platinum group metals are key elements for materials processing. They occur together in one book because they (i) map together on the periodic table (ii) occur together in many ores and (iii) are natural partners for further materials processing and materials manufacturing.

Process Direct Nickel what are the process of mining and extracting nickel ores,The Direct Nickel (DNi) Process is a newlydeveloped and revolutionary Contact Supplier BioHeap A .

1. Introduction to the extraction of metals. What methods can be used in extracting metals from mineral ores? The Earth's crust contains many different rocks.. Rocks are a mixture of minerals and from some we can make useful substances.. A mineral can be a solid metallic or non–metallic element or a compound found naturally in the Earth's crust.

A solvent extraction application consisting of twosequential solvent extraction circuits to separate the nickel and cobalt from a synthetic sulphate leach solution which simulates a typical ...

extraction process. IV. Based on the research that has been be concluded that the extraction of nickel with dimethylglyoxime performed at various pH acidic, neutral and alkaline. The optimum nickel extraction at pH 8 with a linear curve at concentrations of 5 to 25 ppm nickel. (d) extraction .

SXEW, or the Solvent Extraction – Electrowinning approach to lateritic ore beneficiation, is a hydrometallurgical method that relies on leaching, extractants, and electrowinning to produce nickel from ore. This process is often referred to as Leach Solvent Extraction – Electrowinning for its employment of a .

The nickel raw solution coming from the leaching plant to cobalt extraction is cooled and washed with kerosene to prevent foreign organic substances from entering the extraction process. Cobalt extraction is carried out in sequential cobalt extraction cells, where the nickel raw solution flows countercurrent to the extraction solution.

Mar 15, 2013· BINQ Mining > Crusher and Mill > why is limestone added in nickel extraction process; Print. why is limestone added in nickel extraction process. Posted at:March 15, 2013[ 3456 Ratings] ... nickel extraction process – YouTube. and nickel extraction.

different levels was investigated. Therefore, the main objective of the study was to optimize the process parameters for the flotation of base metals from a nickelcopper sulphide ore. 2. Materials and Methods 2. 1. Materials The nickelcopper sulphide ore used in this study was supplied by Trojan Nickel Mine located in Bindura, Zimbabwe.

The samples were representative of typical nickel laterite mined in Indonesia for processing and sourced from a regional property in which the company has no interest.

Jun 27, 2019· Pacific Rim Cobalt Corp. is an exploration company focused on the development of cobalt projects ideally located close to China, the world's first largest "Gigafactory." Cobalt is a critical component of lithiumion batteries and is currently in a global supply deficit.

Jan 15, 2019· The influence of nickel carriers minerals, contained in three different laterite ore samples, on their extraction by a sulfationroastingleaching process, is investigated in this paper. Xray diffraction, scanning electron microscopy coupled to energy dispersive spectroscopy and chemical analyses by atomic absorption spectrometry were the ...

Nov 28, 1995· In a continuous countercurrent process, much as would be practiced commercially, the extraction step is carried out with a series of mixersettler units in which the outlet of a mixer continuously feeds a large settling tank where the organic solvent (organic phase), now containing the nickelextractant complex in solution, is separated from the depleted aqueous solution (aqueous phase).

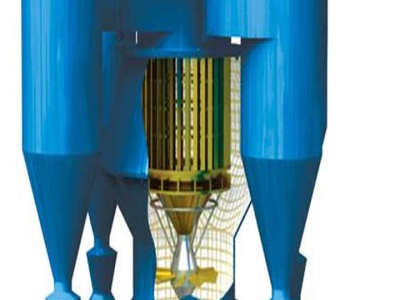

Extraction of nickel from the laterite ores Hydrometallurgical process involves ammoniacal or sulfuric acid leaching followed by nickel precipitatation. In the pyrometallurgical process the ore is dried and calcined in a rotary kiln and then smelted in an electric furnace with addition of carbon .

Iridium is extracted after copper and nickel processing, from a mixture known as anode mud. Once this mixture is dissolved, the iridium is brought to the surface via extraction with organic amines.

![Extractive metallurgy of nickel [SubsTech]1](/i0m6h9y/1466.jpg)

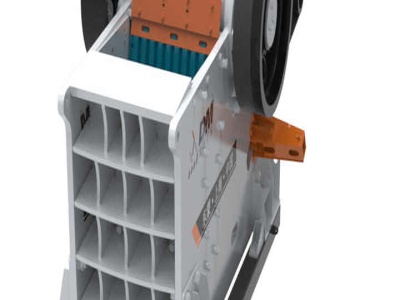

![Extractive metallurgy of nickel [SubsTech]2](/i0m6h9y/511.jpg)