national grid generation based on 60 percent coal, 11 percent natural gas, and 29 percent noncarbon resources rather than generation from 100 percent coal. This would represent about 2 percent of the total annual carbon equivalent emissions. Energy Use in the Steel Industry iii

pdf on raw coal mills

Roller mills are typically used in coal fired power plants and cement plants. In power plants they are used for grinding coal and in cement plants for raw material size reduction as well as for grinding coal. Lately there has been a growing demand for these types of mills for finished cement grinding and the grinding of granulated blast ...

Pulverisers are one of the major auxiliaries in a coal fired thermal power station. They are used for grinding the precrushed raw coal, so that the pulverised product at desired PF fineness can be fed directly to the furnace of the steam generator. BHEL MANUFACTURE BOWL MILLS AND BALL TUBE MILLS 15 65 115 BBD 3448 BBD 4760 BBD 4772

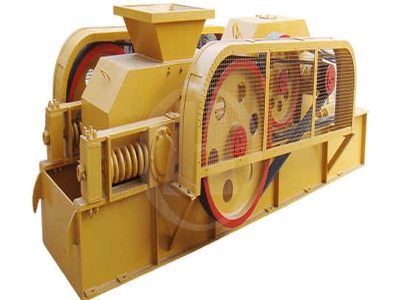

Raw mills and coal mills for cement raw mills and coal mills for cement excellent mining crushing machinery products or production line design, the company is;KALPRAXIS Regeneration of Grinding Components in Roller Mills grinding coal and in cement plants for raw material 1 : Grinding rollers in roller mills .

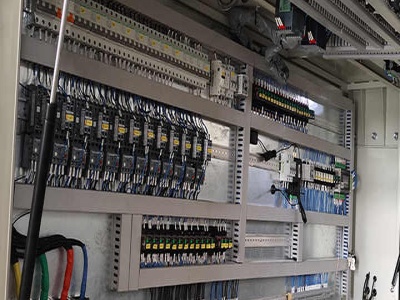

Figure : Typical Mimic sample of the Raw Mill Section 4. ENERGY SCENARIO Electrical Energy System The cement plant receives electricity supply from the Captive Power Plant (CPP) (12 MW) and DG sets. It is distributed to various sections of the plant. An energy meter is installed on 110 kV feeder incomer, which records

Laos 6. Raw Materials and Energy required for production of 1 ton of Cement Limestone 1,095 Clay 204 Silica 78 Ironore 30 Gypsum 34 total 1,439 Raw Materials (kg) (*1) : kg of coal equivalent where HHV of coal is 6,200 kcal/kg.

Bowl Mill. This table is rotated with the help of a motor. There are three large steel rollers, which are spaced 120" apart. When there is no coal, these rollers do not rotate but when the coal is fed to the table it packs up between rollers and the table and this forces the rollers to rotate.

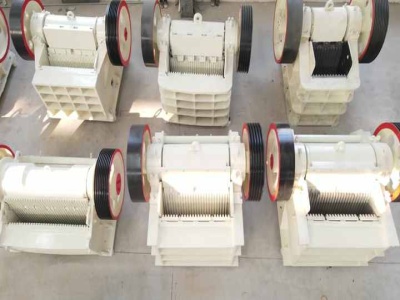

raw mills coal mills in cement plant Raw Mills And Coal Mills For Cement raw mills amp coal mills in cement plant raw mills amp coal mills in cement plant Cement Wikipedia, the free encyclopedia A cement is a binder, a substance that . pre: Quarry Belt Conveyor Speed next: Mesin Hammer Mill Pabrik Kelapa Sawit.

Raw coal coming from feeder gets ground between the grinding rolls and bull ring segments installed on the revolving Bowl. Bowl is made to rotate at medium speed for proper pulverization of coal. Springs exert necessary pressure on rolls for grinding. Hot air through the mill besides removing coal moisture, picks up .

South Africa has iron ore and coal, but, like Brazil, has comparatively high labour costs. China has cheap coal and labour, but buys large volumes of high quality iron ore on the international market. RAW MATERIALS. Raw materials are the main cost differentiator in the steel industry, today more than ever.

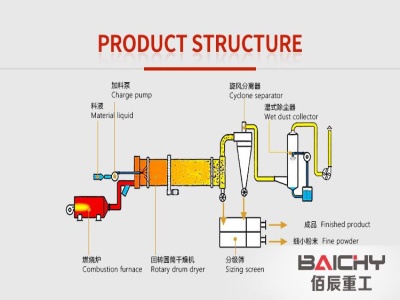

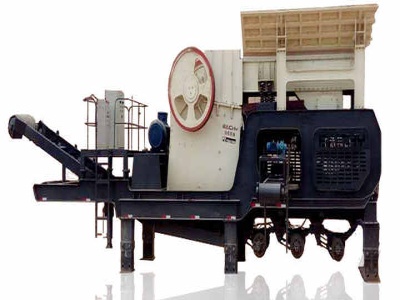

Oct 21, 2013· Coal mill is used to grind, pulverize and dry coal before the coal is transmitted the boiler. The coal is feed into the coal mill via a inlet pipe so that the roller coal mill such as ball mill or vertical mill can pulverize the coal into particles.

coal mill selection pdf coal mill selection pdf impacts plant performance and cost, preparation with an inline raw mill, Coal Preparation " Mill (Grinding) " Gases Coal Preparation Download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online.

Mills are capable of grinding harder coal with higher percentage moisture content and can reduce the product fineness in excess of 90% passing a 200 mesh screen at a reduced output capacity. The feed size of the coal to the mill should be precrushed to 1" top size. Available capacity size range 3,500#/hr.

pulverized coal at the mill outlet is 30%, the gas temperature required at the mill inlet is considered to be approximately 450°C. The evaporation of water in raw coal increases the vapor concentration in the gas at the mill outlet and consequently the O2 level of the primary gas in the burner is expected to be decreased to approximately 9%.

Prior to the coal grinding plant a raw coal pre drying plant will be installed. In a first step the precrushed coal (< 25 mm) will be predried using higher temperatures than allowed for pulverized coal at a reasonable airflow and a low pressure drop. In a second step the coal will be ground to the requested fineness and further dried, if required.

UBE VERTICAL MILL REFERENCE LIST (RAW MATERIAL MILL) Updated : May 2012 134 Mill Type No. Country Delivery Year Grinding Material TOTAL: units 2 Thailand 1991 Raw material