Magnetite (Fe3O4), like hematite (Fe2O3), is a form of iron ore. It is a benign and highly magnetic substance used primarily in steel manufacturing and coal washing. Magnetite occurs in nearly all igneous and metamorphic rocks and usually only in small particles or in a solution with other minerals.

process flow iron production from its ore

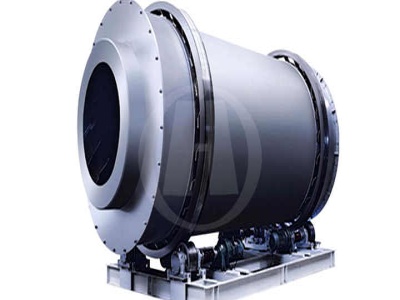

Jan 25, 2019· Galaxy Resources, which mines spodumene at Mt Cattlin in Australia, first crushes and heats the ore in a rotary calcining kiln to convert the lithium crystal phase from alpha to beta. This process is referred to as decrepitation.

Process operates under a slight negative pressure (15 mm WC) Greater raw material flexibility Accepts iron ore, slimes and other iron bearing materials in a wide range of sizes (0 – 20 mm) without any pretreatment Noncoking coals of size 0 – 20 mm with moisture content < 10% are .

OPERATIONAL SIMULATION MODEL OF THE RAW MATERIAL HANDLING IN AN INTEGRATED STEEL ... to million tons which has influenced all its main production equipment and processes. ... the sintering a hot agglomeration process of iron ore fines, coke, fluxing and additions mixture of defined chemical dosages and compositions. The resulting product ...

The Höganäs sponge iron process, is essentially a chemical process in which finely divided iron ore is being reduced with coke breeze yielding a spongy mass of solid metallic iron, which can readily be comminuted to iron powder.

With more than 70% of its earnings derived from iron ore, Rio Tinto's profit is heavily tied to movements in both the prices of the key steelproducing mineral and its underlying cost of production.

On November 6, 2015, ArcelorMittal announced that an agreement had been reached with SIOC to amend the pricing mechanism terms of the current iron ore supply agreement related to Kumba from a costbased price to an Export Parity Price ("EPP") with effect from October 1, 2015.

The raw material processing elements of the system are: (i) the blending the mixture of several materials of distinct characteristics – and, (ii) the sintering a hot agglomeration process of iron ore fines, coke, fluxing and additions mixture of defined chemical dosages and compositions.

The SX/EW Process has its roots in analytical chemistry where it is used to separate one metallic ion from another. It was first used as a largescale process during World War II for the recovery of uranium from its ores. The key to the process is the development of organic extractants that are specific to the metal to be extracted.

Jun 15, 1976· Process of extracting chromium from a chromium ore or concentrate by oxidation, which comprises suspending the chromium ore or concentrate in a bath of molten salts and introducing an oxygencontaining gas into the suspension in a sufficient amount and for a sufficient amount of time to oxidize chromium therein.

Stainless steel is an ironcontaining alloy—a substance made up of two or more chemical elements—used in a wide range of applications. It has excellent resistance to stain or rust due to its chromium content, usually from 12 to 20 percent of the alloy.

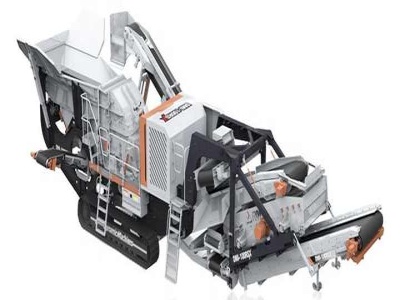

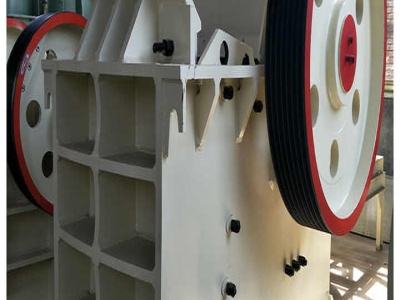

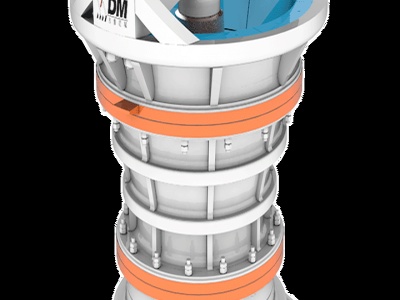

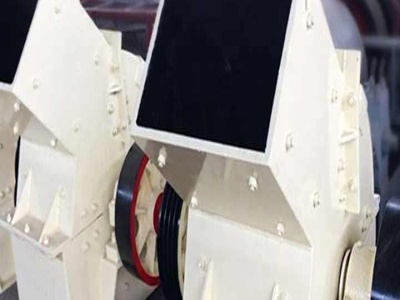

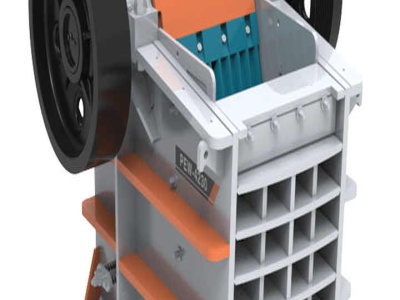

Iron Ore Mining Flow Chart Image Results Free Quote; iron ore mining process flow chart toperminingmachine. iron ore crushing equipment Iron ore is the important raw materials of iron and steel production enterprise, with crushing, grinding, magnetic separation, flotation, election and other procedures to select iron.

Most important, it releases oxygen from the iron ore, which makes up a high percentage of common iron ores. The most primitive facility used to smelt iron is a bloomery. There, a blacksmith burns charcoal with iron ore and a good supply of oxygen (provided by a bellows .

balance calculations for the unit operations of mining, pelletizing, pig iron production, and steel production. •Examine pollution, byproducts of primary metal production, and the importance of scrap recycling. Material Flow Diagrams Life in our world would be impossible without a large flow of materials, a flow

Dec 28, 2012· Iron Ore Extraction Process Flow Diagram | Manganese Crusher Search iron ore extraction process flow diagram to find your need. Zenith Mining and Construction Machinery ... As a leading global manufacturer of crushing and milling equipment, we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete plant.

Alumina is the direct source of aluminium in the aluminium production process, but in order to create the right environment for electrolysis another component is necessary, and that component is cryolite. It's a rare natural fluoride mineral which due to its scarcity in natural form has been manufactured artificially.

Iron Ore Agglomeration Ø Sinter Process The sinter process was introduced around 1910 to treat flue dust extracted from blast furnace exhaust gases. It was quickly adapted to agglomerate fine ore and its use spread rapidly. At the sinter plant, preblended fine ore is mixed with: • coke breeze (small particles of coke from the screening plant);

account for more than 90% of the world production of iron and steel powders, viz. the Höganäs spongeiron process and the wateratomizing process. The former process is based on reduction of iron ore, yielding a highly porous spongeiron which subsequently is comminuted to powder. The latter process is based on atomization of a stream of liquid