Raw Materials The primary component of drywall is the mineral gypsum. It is a lightdensity rock found in plentiful deposits worldwide. Each molecule of gypsum (or dihydrous calcium sulfate) is composed of two molecules of water (H 2 0) and one of calcium sulfate (CaSO 4 ). By weight the compound is 21% water, but by volume it is nearly 50% water.

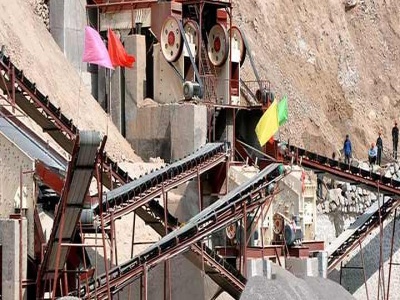

raw gypsum for cement

Gypsum is a raw material used mainly in the production of plasterboard and is also a key ingredient for producing cement. Due to having fireresistant qualities, it has been the material of choice for building structures since ancient times.

Gypsum is a natural mineral mined throughout the world. Glass Fiber Reinforced Gypsum (GFRG) is comprised of a mixture of raw gypsum and cement, laminated to layers of .

Canada, Mexico and Spain are other significant producers of raw gypsum. In all, more than 90 countries produce gypsum. ... Some gypsum is used to make Portland cement, and some is used in agricultural applications. A small amount of very pure gypsum is used in glass making and other specialized industrial applications.

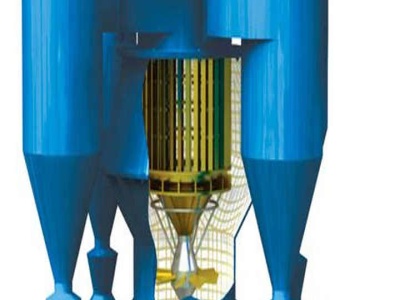

The raw meal is then heated and burned in a preheater and kiln and then cooled in an air cooling system to form a semifinished product, known as a clinker. Clinker (95%) is cooled by air and subsequently ground with gypsum (5%) to form Ordinary Portland Cement ("OPC"). Other forms of cement require increased blending with other raw materials.

Gypsum uses include: manufacture of wallboard, cement, plaster of Paris, soil conditioning, a hardening retarder in portland cement. Varieties of gypsum known as "satin spar" and "alabaster" are used for a variety of ornamental purposes; however, their low hardness limits their durability.

Competitive raw gypsum products from various raw gypsum manufacturers and raw gypsum suppliers are listed above, please select quality and cheap items for you. Besides, we also provide you with related products such as zeolite, pumice stone for your choice.

mined gypsum is 4 2H 2 O) (calcium sulfate dihydrate) Raw gypsum ores are processed to form a variety of of products suiting for products suiting for differentdifferent purposes (portland cement additives, soil conditioners, rheology modifying additives, etc.) When used as a binder in concrete, the most common form is (CaSO. 1 4 / 2 H 2 O ...

Cement Raw Materials British Geological Survey. Cement is a manufactured product made by blending different raw materials and firing ... clinker with 5% gypsum (or anhydrite) which helps to retard the setting time of ....

Clinker is then finally pulverized by grinding into a very fine powder and is finally mixed with calcium sulfatae or gypsum to obtain cement. Raw Materials of Portland Cement. The commonly raw material included in cement is as follow. (a) Calcareous materials and (b) argillaceous materials.

SAFETY DATA SHEET 1. Identification Product identifier HydroStone® Gypsum Cements Other means of identification SDS number HydroStone® TB Gypsum Cement, HydroStone® LF, HydroStone® DL, HydroStone® HD ... Raw materials in this product contain respirable crystalline silica as an impurity. The weight

Cement samples are prepared by method which is displayed below. Raw materials (clinker, gypsum and anhydrite) sieved ( mm) individually by crusher. After this, in the lab mill, the cement samples is the mixture of various ratio of clinker, and gypsum and anhydrite and have 3650±50 cm2/g fineness.

The most important of these is portland cement. This article surveys the historical development of cement, its manufacture from raw materials, its composition and properties, and the testing of those properties. The focus is on portland cement, but attention also is given to other types, such as slagcontaining cement and highalumina cement.

Gypsum is normally only screened to remove 'fines' (mainly mudstones), then crushed and finely ground. Gypsum/Anhydrite for cement manufacture is supplied in crushed form for further fine grinding with cement clinker. C. Processing Natural Gypsum When Gypsum ( CaSO 4,2H 2O) is ground to a powder and heated at 150° to 165° C, three

Apr 17, 2017· Alarmed by a downtrend in gypsum export prices, attributed to unhealthy undercutting by some players, PAM stepped in last month to fix a minimum export FOB price for raw gypsum at US/t, with effect from December 2016.

The Raw Gypsum is offered in the form of lumps having a maximum purity of 98%. The Raw Gypsum has infinite uses in the fields of cement manufacturing, Plaster of Paris manufacturing, as well as the making gypsum boards. Further, the Raw Gypsum is also suitable for agricultural use. The company is the leading Exporter, and Supplier of Raw Gypsum.

Cement Standards and Concrete Standards ASTM's cement and concrete standards are instrumental in the evaluation and testing of concrete, cement, and aggregates. Concrete can have different properties depending upon the mixture that is used in creating it, which contains cement, chemical admixtures, and .

Proportioning of the raw materials is based on a series of simultaneous calculations that take into consideration the chemical composition of the raw materials and the type of cement to be produced: American Society for Testing and Materials (ASTM) Type I, II, III, or V white cement, or American Petroleum Institute (API) Class A, C, G, or H.

The research methodology and calculations for national cement and concrete production (including clinker, cement kiln dust, gypsum, and aggregates) and the resulting datasets help to make projections that shape policy requirements for Thailand and other emerging economies as .

Our Group Co., established in 1998 is a Mine Owner and Manufacturer of Gypsum range of products, such as Raw Gypsum, Gypsum Powder, Gypsum Special Plasters serving Fertilizer, Cement Building Construction Industries.

The raw materials of fiber cement board are cellulose fiber, silicate cement, quartz sand, water and some additives It's a kind of hightech product which formed through accurate dosing by computer program, hatcheck craft and compressed by 14000tons hydraulic machine and .

raw material gypsum in nigeria use of desulfurization gypsum in cement industry. gypsum is a waste material produced in desulfurization of flue gases in High demand for gypsum in Nigeria The annual demand of raw gypsum by Nigeria39, s cement. Get Price And Support

Canada, Mexico and Spain are other significant producers of raw gypsum. In all, more than 90 countries produce gypsum. ... Some gypsum is used to make Portland cement, and some is used in agricultural applications. A small amount of very pure gypsum is used in glass making and other specialized industrial applications.

A ball mill is a rotating drum filled with steel balls of different sizes (depending on the desired fineness of the cement) that crush and grind the clinker. Gypsum is added during the grinding process to provide means for controlling the setting of the cement. The cement is bagged transported for concrete .