The Concrete Construction Process. Proper curing of concrete generally comes down to two factors, keeping it moist and keeping it supported. Hydration of cement, as the word itself implies, involves reaction with water. To cure properly, the cement paste must be fully saturated with water.

stages in cement production

Cement Production: From Clinker Production to the End Product Perfectly mixed, accurately fed without pulsation, and precisely weighed 3. Clinker production. Schenck Process's MULTICOR® K massflow feeding system plays the main role in the second cement production stage.

Overview of Cement Production Cement is an important construction ingredient around the world, and as a result, cement production is a significant source of global carbon dioxide (CO2 ) emissions, making up approximately percent of global CO2 emissions from industrial and energy sources (Marland et al., 1989). Cement is produced in large ...

Energy consumption and output. A typical general purpose Portland cement of fineness (specific surface) 340 m².kg 1 ground on an efficient closedcircuit ball mill system requires around 32 kWh per tonne, so a 10 MW mill would produce 313 tonnes of this per hour. .

Cement. A cement is a binder, a substance used for construction that sets, hardens, and adheres to other materials to bind them together. Cement is seldom used on its own, but rather to bind sand and gravel ( aggregate) together. Cement mixed with fine aggregate produces mortar for masonry, or .

Raw Materials. Portland cement, the kind most often used in concrete, is made from a combination of a calcareous material (usually limestone) and of silica and alumina found as clay or shale. In lesser amounts, it can also contain iron oxide and magnesia. Aggregates, which comprise 75 percent of concrete by volume,...

The cement production process begins with the extraction of limestone and clay from the quarry. The material is then blended, crushed and fed to the kiln. Postkiln, the clinker is cooled and goes through a final grinding method before it is ready to ship.

Cement Cement is the largest operating segment within Höganäs objective is to contribute to a qualitative and costefficient production of cement among the customers. This is achieved by creating optimal use of refractory products through the whole production process – from the cyclone tower to the cooler.

Cement production in 1929 reached a peak of 7,369,000 barrels, fell to 2,973,000 barrels in 1933, and rose to 8,036,515 barrels from ten plants in 1945, when Texas was the secondlargest producer and consumer of cement in the United States. The principal use of cement .

Aug 30, 2012· Cement Manufacturing Process Phase 1: Raw Material Extraction. Cement uses raw materials that cover calcium, silicon, iron and aluminum. Such raw materials are limestone, clay and sand. Limestone is for calcium. It is combined with much smaller proportions of sand and clay. Sand clay fulfill the need of silicon, iron and aluminum.

Cementing through pipe and casing. Conductor, surface, protection, and production strings are usually cemented by the singlestage method, which is performed by pumping cement slurry through the casing shoe and using top and bottom plugs.

The most common AFt and AFm phases in hydrated cement are: Ettringite: ettringite is present as rodlike crystals in the early stages of reaction or sometimes as massive growths filling pores or cracks in mature concrete or mortar.

The details of the cement making process vary widely. However, the fundamental stages in cement production are all the same and as follow. A schematic diagram of the cement manufacturing is shown in • 1. The raw materials are reduced to fine particle size. • 2. Raw materials are blended and mixed to produce uniform chemical

Dry Kilns with Multistage Preheaters and Precalcination. ... As of 2007, only 45% of the Chinese cement production capacity was employing dry kilns with multistage preheaters and precalcination. (Tshinghua University, 2008) ... Dry Kilns with Multistage Preheaters and Precalcination Publications.

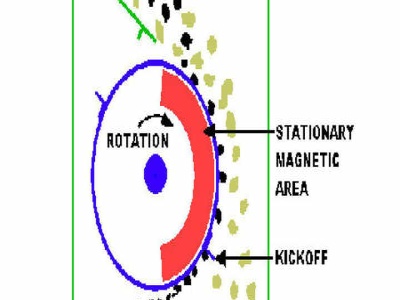

The heart of clinker production is the rotary kiln where the pyroprocessing stage occurs. The rotary kiln is approximately 20 to 25 feet (ft) in diameter and from 150 ft to well over 300 ft long; the kiln is set at a slight incline and rotates one to three times per minute.

Overall, this is immediately apparent from the flow diagram that cement production has five stages which start from crushing limestone and clay and it ends on packing cement in the bag. Beside it, concrete production has just three steps which are staring with mixing all material and ending on its output.

Aug 19, 2011· Global cement production was in 2010, excluding Chinese statistics that claim production of /yr in 2010. 14 Although China represents a major manufacturer and consumer of cement, there is wellinformed skepticism surrounding its claim to produce as much cement as the rest of the world combined. 17

Manufacturing Process of Ordinary Portland Cement (OPC) The manufacturing process of Ordinary Portland cement is made primarily from calcareous and argillaceous materials, such as limestone or chalk, and from aluminium oxide, silica oxide, ferric oxide and magnesium oxide found as clay or shale.