Solargrade Si requires a purity of %. Conventional refining processes for Si invo lve a large environmental load and high cost. We are developing a refining process using electron beams. Melted in a vacuum, some impurities evaporate preferentially from molten Si. Recycling of Precious Metals Refinement of Molten Silicon Evaporated species are

vacuum distillation refining of metallurgical grade silicon

Calcium Evaporation from Metallurgical Grade Silicon by an Electron Beam Melting 作者: Wei Dong, Xu Peng, Da Chuan Jiang, Yi Tan, Qiang Wang, Guo Bin Li 摘要: In order to investigate Ca evaporation behavior in the electron beam melting process, metallurgicalgrade silicon was melted in an electron beam furnace with different experimental conditions.

The book Complete Technology of Lubricating Oils, Synthesis of Lubricants Additives, ReRefining of used Lubricating Oil, Base Oil and Greases Manufacturing with Formulations covers Manufacture of Products, Extra Temperature Lubricating Grease, Synthesis of Lubricant's Additives, Calcium Base Grease, Re Refining of used lubricating oil, Food Grade Grease or Lubricant, Lubricant Base Oil Hydrotreatment .

An integrated process development unit for converting metallurgical silicon and hydrogen to highpurity silane has been commissioned. A quartz fluidbed reactor capable of operating at temperatures of up to 1000/sup 0/C was designed, constructed, and successfully operated.

Refining of metallurgical silicon by directional ... Refining of metallurgical silicon ... whereby the metallurgical grade silicon ... the liquid was poured into a cylindrical mold made of solar grade fused quartz ... Contact Supplier

In vacuum distillation, generally used to produce roadtar asphalt, the residual is heated to about 750° F and charged to a column where vacuum is applied to prevent cracking. b. Asphalt for roofing materials is produced by air blowing.

about 525°C under dynamic vacuum. The material depo sited over the water cooled SS fingers was then su bjec ted to ICP –OES analysis. The overall purity of trace impurity elements was more than 99 ⋅995% except sel enium which is around 115 ppm. The gaseous impurities like oxygen and nitrogen in vacuum distilled tellurium was analysed

Pre refining of metallurgical grade silicon or postrefining of the product may be performed, depending on the initial impurity content of the feedstock, to obtain Si that meets solar grade requirements.

The patented, closedloop silane manufacturing process used by REC Silicon produces consistent, ultra pure silane by conversion of metallurgical grade silicon into trichlorosilane and redistribution/ distillation to .

Mar 05, 2015· Standard silicon solar cell. 49. Vacuum evaporation Metal contact are then attached to both the n type and the ptype region,the metal to be deposited is heated in a vacuum to a high enough temp to cause it to melt and vaporize, it will then condense on any cooler parts of the vacuum system in direct line of sight,...

Metallurgical grade silicon is commercially prepared by the reaction of highpurity silica with wood, charcoal, and coal in an electric arc furnace using carbon electrodes. At temperatures above 1900 °C (3,450 °F) carbon reduces silicon to silicon metal.

Therefore, many efforts have been done to obtain reliable metallurgical methods for production of SoG silicon from metallurgical grade silicon.

显示简单条目. Precipitation phase and impurities distribution of metallurgical grade silicon by vacuum refining followed slag treatment

A combined slagging and gas blowing refining technique for boron removal from metallurgical grade silicon using the CaOSiO 2CaCl 2 slag and the mixed ArO 2H 2 O gas is investigated. The oxygen gas blowing in combination with water vapor shows a wonderful removal efficiency of boron compared with the single oxygen or the single water vapor ...

Petroleum Coke is defined as a black solid residue obtained by cracking and carbonising of petroleum derived feedstocks, vacuum bottoms, tar pitches in processes such as delayed coking or fluid coking. Petroleum coke is a byproduct of the oil refining process.

Silicone oil. A silicone oil is any liquid polymerized siloxane with organic side chains. The most important member is polydimethylsiloxane. These polymers are of commercial interest because of their relatively high thermal stability and their lubricating properties.

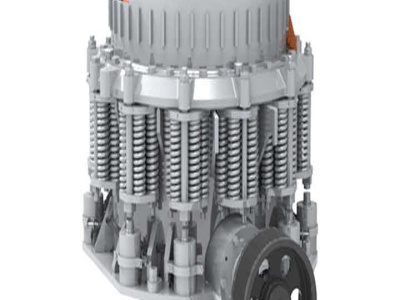

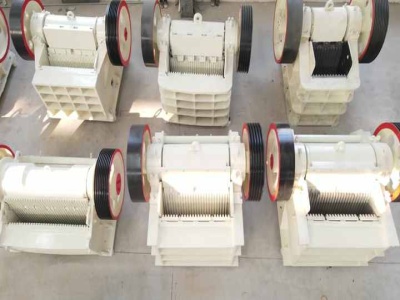

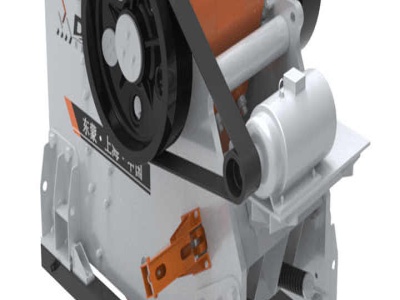

silicon carbide sintering furnace; vacuum brazing furnace; Vacuum heat treatment furnace; Vacuum melting equipment; Vacuum sintering furnace ; vertical vacuum furnace; heat treatment furnace of hydrogen; PL2000 Permanent Magnet Lifter Crane for Metal Scrap. Inquire. Strong Electro Magnetic Lifter for Lifting Metal Scrap. Inquire.

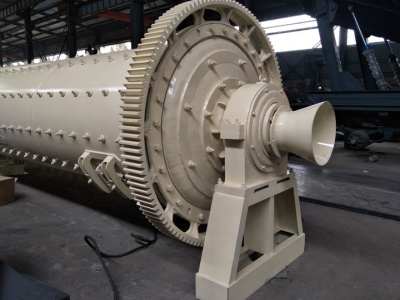

A less expensive method to obtain electronicgrade silicon from metallurgicalgrade silicon, is the refining by metallurgical routes to remove the impurities (Fe, Al, Ti, Mn, B, P, O, and C) from the silicon matrix. The key technique of this process is the directional solidification [11] in a zone furnace.

Jan 14, 2019· The same method, without the inclusion of iron, is used to produce metallurgical grade silicon that is greater than 99 percent pure. Metallurgical silicon is also used in steel smelting, as well as the manufacture of aluminum cast alloys and silane chemicals.

Abstract. This paper presents a detailed analysis of the effect of slag refining and vacuum treatment on P removal from metallurgicalgrade silicon using CaOSiO2CaCl2 slag. It demonstrates that both of CaO: SiO2 ratio and CaCl2 content have significant effects on the P removal.

WetChemical Etching and Cleaning of Silicon: A Introduction. Research and manufacturing related to silicon devices, circuits, and systems often relies on the wetchemical etching of silicon wafers. The dissolution of silicon using liquid solutions is needed for deep .

Crystal Structure and Growth Source: USNA EE 452 Course on IC Technology. EE452 13 ... • Si is purified from SiO2 (sand) by refining, distillation and CVD. • Bulk silicon is first processed in polycrystalline form ... Produce metallurgical grade silicon (MGS) by heating silica with carbon (furnace) ...

The silica in the quartz sand is reduced in an arc furnace to obtain metallurgical grade silicon, which is then purified further into electronic grade or solar grade silicon. This is done either by the Siemens process in which a reactor with silane and hydrogen gases are heated to 1 1001 200C for growing silicon rods, or the modified Siemens process in which the silane and hydrogen gases are heated to ~800 C.

silicon stlione refinding equipment ; Chemicals, Petroleum Refining, Rubber and Plastics, Every Chemicals, Petroleum Refining, Rubber and Plastics Products in Canada See full local business information including address and phone [Chat Online] silica refining equip indiaigdbombayartcoin.